I. Introduction

On December 14, 2020, the State Administration for Market Regulation (National Standardization Administration) approved the release of the "Recycled Iron and Steel Raw Materials" (GB/T 39733-2020) recommended national standard, which will be officially launched on January 1, 2021 Implement. The issuance and implementation of the national standard of "Recycled Steel Raw Materials" will play an active role in improving the quality of high-quality recycled steel raw materials, promoting energy conservation and emission reduction, green development, and effective use of foreign ferrite resources in the steel industry, and will contribute to the high-quality development of the industry. Important strategic significance.

2. The main development process of the standard

On March 9, 2020, the Metallurgical Industry Information Standards Research Institute, China Scrap Iron and Steel Application Association and other units applied to formulate the national standard of "Recycled Iron and Steel Raw Materials", which was approved by the China Iron and Steel Industry Association and reported to the National Standardization Management Committee.

On April 7, 2020, the Ministry of Ecology and Environment organized relevant units to hold a video conference to coordinate and solve the main problems of imported recycled steel raw materials.

On May 22, 2020, the Standards Preparation Working Group organized a standards seminar in Tianjin. More than 50 units and more than 100 experts attended the meeting.

On July 28, 2020, the standard preparation working group organized a standard seminar in Shanghai.

On September 23, 2020, the Ministry of Ecology and Environment and other departments organized a standards coordination meeting in Beijing.

On September 30, 2020, the standard preparation working group held a seminar in Beijing.

On October 13, 2020, the national standard launch meeting for "Recycled Steel Raw Materials" was held in Shanghai.

On October 24, 2020, the national standard of "Recycled Iron and Steel Raw Materials" was open to solicit opinions from the society.

On November 29, 2020, the national standard review meeting for "Recycled Steel Raw Materials" was held in Beijing.

On December 14, 2020, the national standard for "Recycled Steel Raw Materials" was approved and released.

3. The main content of the standard

1. The scope of application of the standard

The national standard of "Recycled Iron and Steel Raw Materials" mainly stipulates terms and definitions, classifications, technical requirements, inspection methods, and acceptance rules; the scope includes recycled iron and steel materials used as raw materials for ferrite charge in ironmaking, steelmaking, casting and ferroalloy smelting .

The new standard is not only applicable to the processing and treatment of domestic recycled steel raw materials resources, but also applicable to the import of recycled steel raw materials resources that meet the requirements of international standards.

2. Standard terms and definitions

The terms and definitions of the national standard "Recycled Steel Raw Materials" include recycled materials, recycled steel raw materials, inclusions, sorting, shearing, crushing, and packing. It involves definitions that need to be defined in the attributes, main technical indicators, and processing processes of recycled steel raw materials.

1) In terms of properties of recycled steel raw materials:

Clarify the definition of "recycled material". Refers to steel products or steel scraps that have lost their original use value or have not lost their use value but have been abandoned or abandoned, which is equivalent to "scrap steel".

"Recycled iron and steel raw materials" are charge products that can be used directly into the furnace as ferrite resources after sorting and processing recycled materials. It is clarified that "recycled iron and steel raw materials" are charge products, which are ferritic charge materials that have been classified and processed to meet environmental protection technical requirements.

2) Main technical indicators:

Clarify the definition of "inclusion". Non-metallic substances mixed into recycled iron and steel raw materials during production, collection, packaging and transportation, including wood waste, waste paper, waste plastics, waste rubber, waste glass, rocks, and powdery materials with a particle size not greater than 2 mm ( Dust, sludge, wood chips, fiber powder, etc.), but does not include packaging and other materials used during transportation.

3) Processing aspects:

Clarify the processing technology of sorting, dismantling, cutting, crushing, and packing, and emphasize the processing process of recycled steel materials.

For example, "sorting" is the process of sorting and screening recycled steel products according to the requirements of chemical composition, physical specifications, use, etc., and separating them from other substances to become a specific type of recycled steel raw materials. "Shearing" is the process of cutting or shearing recycled steel products into recycled steel raw materials with physical specifications that meet the requirements. "Packing" is the process of pressing recycled steel products using professional equipment into a block-type recycled steel raw material.

3. Standard classification and grade

The national standard of "Recycled Iron and Steel Raw Materials" emphasizes classification and processing.

The standard is clear: Recycled steel raw materials are divided into 7 categories according to physical specifications and chemical composition through different processing methods. Namely: heavy, medium, small, crushed, bale, alloy steel, cast iron and other 7 types of recycled steel raw materials.

According to the raw material source and quality characteristics, the recycled steel raw materials are divided into 18 grades. Each grade explains the raw material properties and typical examples.

The following is an overview of the classification and grades of recycled steel raw materials from 7 aspects.

Ⅰ. Heavy-duty recycled steel raw materials: generally refers to solid bodies with a thickness of 6.0mm or more or a diameter of 10mm or more, length ≤1500mm; width ≤600mm; unit weight ≤1500kg.

Set 2 grades.

HRS101: The source of raw materials is steel products decommissioned after a certain service life, including various scrapped large equipment, railway scrapped equipment materials, various scrapped large steel structure parts, various scrapped large ships, etc. Such as: large machine tools, industrial and mining machinery, steel rails, wheels, axles, steel structures, steel pipes, section steels, plates and various old steel materials.

HRS102: The source of raw materials is leftovers or tailings formed in the production or processing process, including cut ends, defective products, and degraded products produced in the steel production process. Such as: cutting head and tail of steel ingots or billets; defective steel billets; residual materials or tailings produced after steel plate stamping.

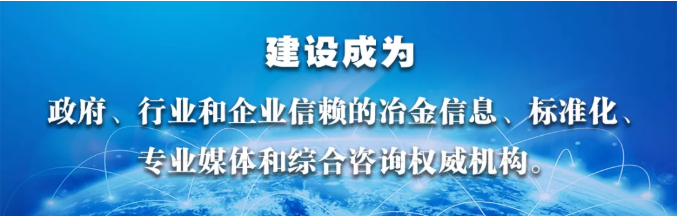

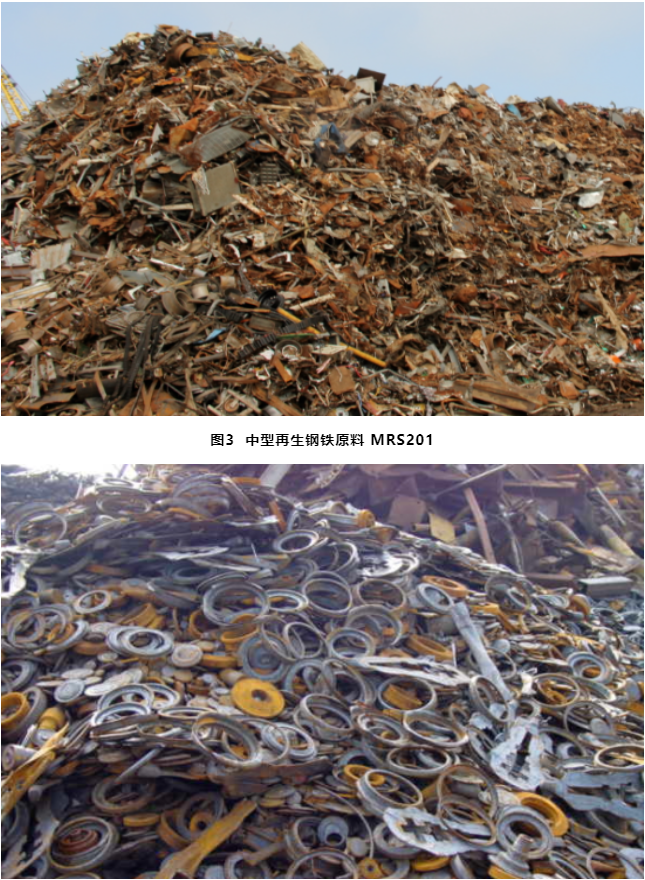

Ⅱ. Medium-sized recycled iron and steel raw materials: generally refers to solid bodies with a thickness of 4.0mm or more or a diameter of 8mm or more, length ≤1500mm; width ≤600mm; unit weight ≤1500kg.

Set 2 grades.

MRS201: The source of raw materials is steel products decommissioned after a certain service life, including various scrapped small and medium-sized equipment, medium-sized steel structural parts, small and medium-sized ships, etc. Such as: small and medium-sized machine tools, industrial and mining machinery, various small and medium-sized parts, steel castings, various steel plates produced by dismantling or repairing small and medium-sized ships, etc.

MRS202: The source of raw materials is leftovers or tailings formed during the processing of various steels. Such as: the remnants or tailings produced in the process of various steel processing, the remnants or tailings produced after the steel plate stamping.

Ⅲ. Small-scale recycled steel materials: generally refer to recycled steel materials with a thickness of more than 2.0mm, and also include new materials with a thickness of less than 2.0mm. Length≤1500mm; width≤600mm; unit weight≤1500kg.

Set 3 grades.

LRS301: The source of raw materials is steel products that are decommissioned after a certain number of years of use, including various scrapped small equipment, various scrapped small motor vehicles or electric vehicle frames, etc. Such as: various scrapped small equipment, spare parts, life hardware, etc.

LRS302: The source of raw materials is leftovers or tailings formed during the processing of various steels. Such as: all kinds of steel (section steel, round steel, angle steel, steel plate) in the process of processing residual materials or tailings; residual materials or tailings generated after steel plate stamping.

Grade LRS303: The thickness is less than 2.0mm, a new material formed during the processing of various steels. Such as: residual materials or tailings generated during the processing of automotive panels and home appliance panels.

0086-717-6731227

0086-717-6731227

The 2nd Avenue Longxi Road, Xiling Economic

The 2nd Avenue Longxi Road, Xiling Economic

Development Zone in Yichang City, Hubei Province

Technical Support:![]()